Industrial Assembly Services

Specialized clinch nut and rivnut assembly solutions designed for speed, accuracy, and reliability in aluminum extrusions.

Trusted by Industry Leaders

Assembly Challenges Slowing You Down?

Offers top-tier comprehensive industrial assembly services, AMG Industries is delivering high-quality, finished assemblies.

Inconsistent Fastening

Threaded inserts fail quality checks or don’t hold under stress.

Manual and Slow Processes

Your current process lacks speed or repeatability.

Fitment Issues

Inserts don’t align, causing delays or rework in downstream assembly.

Automated and Inspected Assembly Services

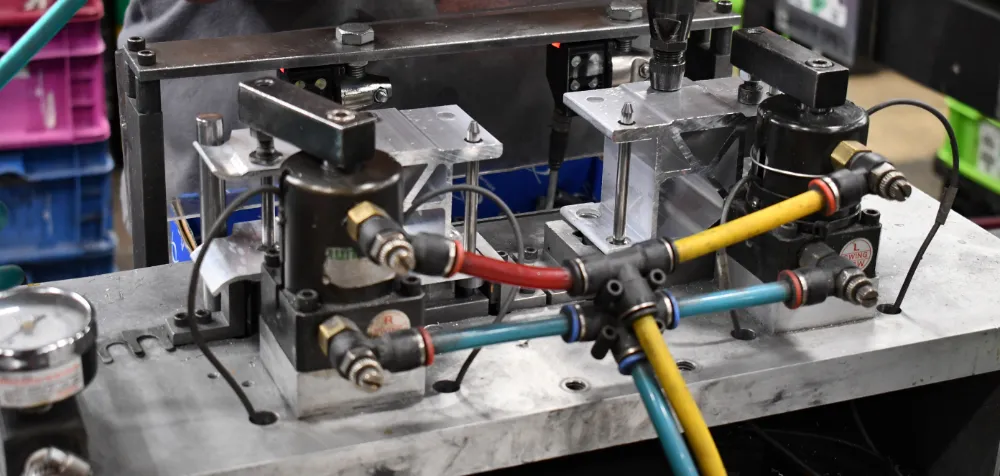

At AMG, our assembly process combines pneumatic/hydraulic clinching machines with calibrated torque testers and vision inspection systems for unbeatable precision.

We specialize in installing clinch nuts and rivnuts into aluminum extrusions, supporting a wide range of sizes, geometries, and part volumes.

Every insert is validated using calipers, torque testing, and visual systems to ensure compliance with client tolerances and standards.

Need added value? We also provide surface finishing, coating, or part marking post-assembly to meet your final spec.

Why Manufacturers Choose AMG for Assembly

TORQUE-VERIFIED CONNECTIONS

Every nut or rivnut is tested to spec before delivery.

TIGHT TOLERANCES MAINTAINED

We use calibrated inspection tools and process documentation for consistency.

BUILT FOR YOUR SPEC

From simple installs to multi-step assemblies, we tailor to your needs.

Why Choose AMG for Assembly Services?

Clinching + Riveting Expertise

Precision tools and processes for aluminum extrusion fasteners

Vision and Torque Testing

Every connection gets verified before shipping

Flexible Tooling Systems

Supports various nut types, extrusion sizes, and production volumes

Surface Finishing Available

Post-assembly treatment, marking, and packaging as needed

ISO 9001 Certified

Trusted by top OEMs and built on documented processes

Assembly Specifications

| Capability | Details |

|---|---|

| Assembly Services | Specialization: Clinch nuts and rivnuts into aluminum extrusions Equipment: Advanced clinching machines (pneumatic/hydraulic), rivnut tools (hand-operated, pneumatic, electric), torque testers, calipers, vision systems Process: Preparation (cleaning, alignment), insertion (precision tools), clinching/riveting (controlled force), inspection (torque, dimensional, visual), finishing (additional processes) Benefits: Precision, efficiency, flexibility, quality assurance Applications: Automotive sub-assembly, industrial sub-assembly, custom kit services |

Assembly FAQs

Our Precision Assembly Process

Preparation

Before installation, we meticulously prepare the aluminum extrusions, ensuring they are clean, free from contaminants, and properly aligned for the insertion of clinch nuts or rivnuts.

Preparation

Before installation, we meticulously prepare the aluminum extrusions, ensuring they are clean, free from contaminants, and properly aligned for the insertion of clinch nuts or rivnuts.

Insertion

Using precision tools and fixtures, our skilled technicians insert the clinch nuts or rivnuts into the designated positions on the aluminum extrusions. Care is taken to maintain alignment and prevent damage to the extrusions during this critical phase.

Insertion

Using precision tools and fixtures, our skilled technicians insert the clinch nuts or rivnuts into the designated positions on the aluminum extrusions. Care is taken to maintain alignment and prevent damage to the extrusions during this critical phase.

Clinching/Riveting

With the clinch nuts or rivnuts in place, our specialized machinery applies controlled force to deform the nuts or compress the rivets, creating a secure and permanent connection within the extrusions. This process is executed with precision to achieve optimal thread engagement and mechanical strength.

Clinching/Riveting

With the clinch nuts or rivnuts in place, our specialized machinery applies controlled force to deform the nuts or compress the rivets, creating a secure and permanent connection within the extrusions. This process is executed with precision to achieve optimal thread engagement and mechanical strength.

Inspection

Each extrusion undergoes rigorous inspection using our quality control instruments. Torque testing ensures the integrity of the threaded connections, while dimensional checks guarantee adherence to specifications. Visual inspection systems identify any defects or irregularities for immediate correction.

Inspection

Each extrusion undergoes rigorous inspection using our quality control instruments. Torque testing ensures the integrity of the threaded connections, while dimensional checks guarantee adherence to specifications. Visual inspection systems identify any defects or irregularities for immediate correction.

Finishing

Upon passing inspection, the extrusions may undergo additional finishing processes as required by the client, such as surface treatment, coating, or marking. These final touches enhance the appearance and functionality of the components, readying them for assembly or distribution.

Finishing

Upon passing inspection, the extrusions may undergo additional finishing processes as required by the client, such as surface treatment, coating, or marking. These final touches enhance the appearance and functionality of the components, readying them for assembly or distribution.

LATEST INSIGHTS FROM AMG INDUSTRIES

Showing our latest insights while we continue to publish more content on this topic.

How to Compare Metal Fabrication Suppliers and What to Look For

By Melissa Brooks

Thu Jul 24 2025

Learn how to evaluate and compare metal fabrication suppliers with this comprehensive guide covering quality, capabilities, pricing, and more.

Read More

How to Request a Metal Fabrication Quote: What Buyers Need to Know

By Melissa Brooks

Mon Jun 16 2025

Learn the essential steps for requesting accurate metal fabrication quotes, from preparation to comparison. Expert tips to get the best value and avoid common mistakes.

Read More

How Custom Metal Components Improve Product Performance and Design

By Melissa Brooks

Fri Jun 06 2025

Discover how custom metal components enhance product performance, design freedom, and user experience. Learn about material optimization, manufacturing processes, and real-world applications.

Read More

Precision Assembly That Fits Your Operation

Let AMG handle the fastening so you can focus on the finished product. Start your next project with our expert assembly services.

Request Assembly QuoteTrusted by Industry Leaders