Agriculture Laser Cutting Services

Precision laser cutting solutions for agricultural equipment manufacturers. Our advanced fiber optic technology delivers the accuracy and durability needed for farming machinery, from tractor components to harvester parts that withstand demanding field conditions.

Trusted by Industry Leaders

Traditional Cutting Limiting Your Agricultural Equipment Manufacturing?

Agricultural equipment demands precision components that can withstand harsh field conditions. Traditional cutting methods create bottlenecks that modern agricultural manufacturers can't afford.

Poor Weather Resistance

Traditional cutting leaves rough edges and burrs that create weak points, leading to premature failure in harsh agricultural environments.

Limited Equipment Design Flexibility

Complex agricultural machinery shapes and precision mounting holes are expensive or impossible with conventional cutting methods.

High Seasonal Tooling Costs

Traditional cutting requires expensive dies that delay equipment updates needed for changing agricultural seasons and crop requirements.

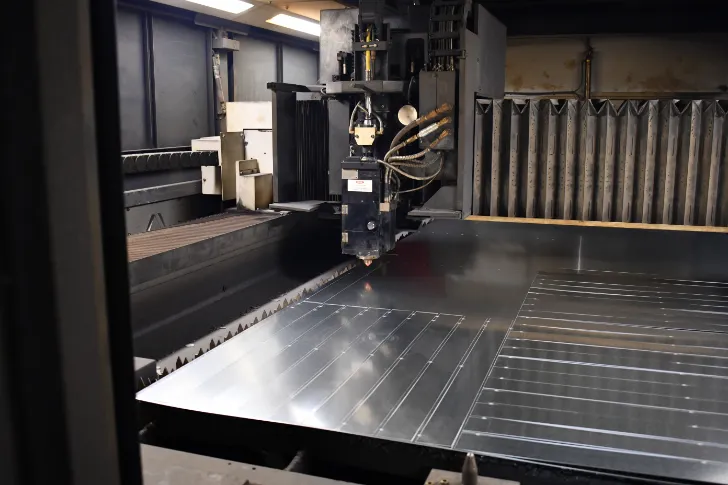

Advanced Laser Cutting for Agricultural Excellence

Our Mitsubishi ML3015eX F40 fiber optic laser systems deliver the precision and consistency agricultural equipment manufacturers need. With 8000 watts of cutting power, we process the heavy-duty materials required for tractors, harvesters, tillers, and other farming equipment.

Agricultural components demand superior edge quality to withstand weather, soil conditions, and heavy mechanical stress. Our nitrogen-atmosphere cutting eliminates oxidation while delivering burr-free edges that resist corrosion and extend equipment life.

From prototype farm equipment to high-volume production of combine harvester components, our laser cutting accommodates the seasonal demands of agricultural manufacturing. Quick setup times ensure you meet critical planting and harvest deadlines.

Agricultural Laser Cutting Advantages

FIELD-READY PRECISION

Clean, corrosion-resistant edges with ±0.005" tolerances ensure agricultural components perform reliably in demanding field conditions.

SEASONAL FLEXIBILITY

No tooling requirements enable rapid production changes for seasonal equipment modifications and emergency repairs.

COMPLEX AGRICULTURAL GEOMETRIES

Intricate equipment designs for modern precision agriculture are easily accommodated without expensive tooling investments.

Why Agricultural Equipment Manufacturers Choose AMG?

Agricultural Equipment Expertise

Decades of experience manufacturing components for John Deere and other agricultural leaders

Heavy-Duty Material Processing

Cut thick steel, stainless, and aluminum up to 12.7mm for robust agricultural applications

Weather-Resistant Quality

Nitrogen atmosphere cutting prevents oxidation for superior corrosion resistance in field conditions

Seasonal Production Flexibility

Rapid setup capabilities to meet critical agricultural manufacturing deadlines

Fast Turnaround

We prioritize quick delivery to keep your farm equipment running with minimal downtime

Durable Parts

Our laser-cut components are built to endure the demands of agricultural work

Cost Efficiency

Precision laser cutting minimizes material waste, saving you money on every part

Custom Replacement Parts

We can replicate worn components with exact precision for seamless replacements

ISO 9001:2015 Quality

Certified quality systems ensuring consistent agricultural component performance

Complete Agricultural Solutions

Integrated stamping, welding, and finishing services for complete equipment assemblies

Agricultural Laser Cutting Specifications

| Capability | Details |

|---|---|

| Laser Cutting | Equipment: Two Mitsubishi 2D flat bed laser cells with ML3015eX F40 lasers Technology: Fiber optic Materials: Carbon steel, stainless steel, aluminum, steel Specifications: Maximum laser output 8000 watts, cutting thickness 6.35 mm, nitrogen atmosphere Benefits: High precision, custom fixtures, optimized setup, low tooling cost for high-volume and prototypes |

Agricultural Manufacturing Insights

Showing related content plus our latest insights to give you more valuable information.

How to Compare Metal Fabrication Suppliers and What to Look For

By Melissa Brooks

Thu Jul 24 2025

Learn how to evaluate and compare metal fabrication suppliers with this comprehensive guide covering quality, capabilities, pricing, and more.

Read More

Sheet Metal Fabrication: A Step-by-Step Guide to the Process and Applications

By Melissa Brooks

Thu Apr 10 2025

Learn the complete sheet metal fabrication process from design to finishing. Discover materials, applications across industries, and best practices for successful projects.

Read More

How to Request a Metal Fabrication Quote: What Buyers Need to Know

By Melissa Brooks

Mon Jun 16 2025

Learn the essential steps for requesting accurate metal fabrication quotes, from preparation to comparison. Expert tips to get the best value and avoid common mistakes.

Read More

Agriculture Laser Cutting FAQs

Ready to Enhance Your Agricultural Equipment Manufacturing?

Partner with AMG Industries for precision laser cutting solutions that meet the demanding requirements of modern agricultural equipment.

Request a QuoteTrusted by Industry Leaders