Agriculture Metal Stamping Services

Precision metal stamping solutions for agricultural equipment manufacturers. Our heavy-duty stamping capabilities deliver the durable, weather-resistant components needed for tractors, harvesters, and farming machinery that work season after season.

Trusted by Industry Leaders

Metal Stamping Challenges Limiting Your Agricultural Equipment?

Agricultural equipment demands components that can withstand extreme field conditions, seasonal stress, and heavy mechanical loads. Traditional stamping limitations can compromise equipment reliability.

Weather Damage Failures

Poorly stamped agricultural components fail prematurely due to corrosion, stress fractures, and insufficient material thickness for field conditions.

Seasonal Production Delays

Inconsistent stamping quality and delivery delays disrupt critical agricultural equipment manufacturing deadlines during planting and harvest seasons.

Equipment Downtime Costs

Defective stamped parts cause expensive equipment failures during critical farming operations when downtime costs thousands per day.

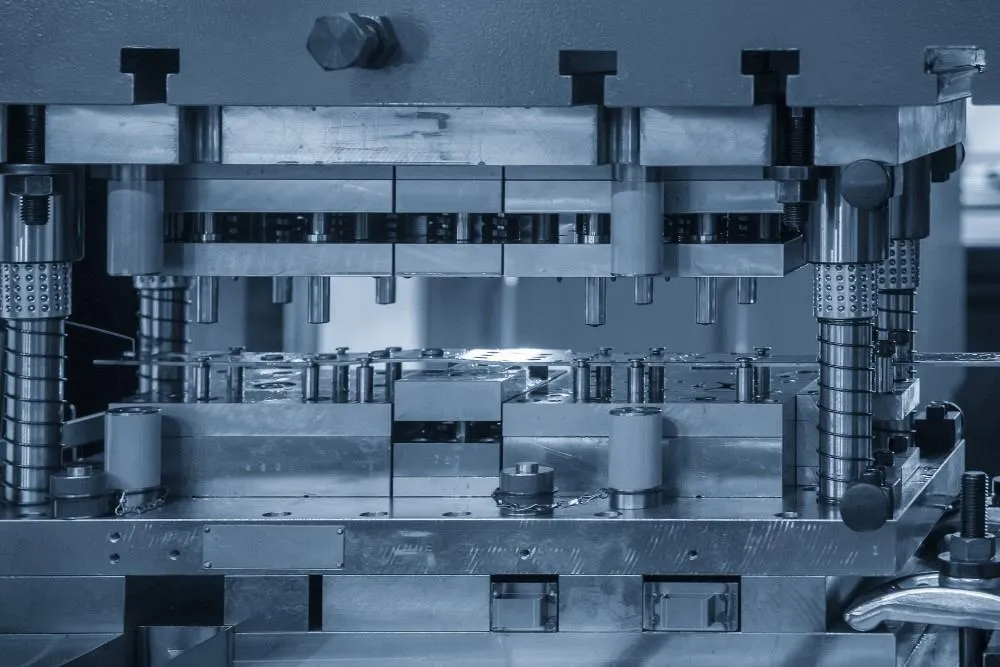

Heavy-Duty Stamping for Agricultural Excellence

Our 20 precision stamping presses, ranging from 18 to 300 tons, are specifically equipped to handle the heavy-gauge materials required for agricultural equipment. We stamp thick steel, stainless steel, and corrosion-resistant alloys that withstand years of field exposure.

Agricultural components demand exceptional strength and precision. Our progressive die systems create complex tractor parts, combine harvester components, and tillage equipment pieces with the tight tolerances needed for modern precision agriculture.

From prototype farm equipment to high-volume production runs, our ISO 9001:2015 certified processes ensure every agricultural component meets the demanding standards required for reliable field performance. Our experienced tool and die team understands the unique stresses agricultural equipment faces.

Agricultural Metal Stamping Advantages

FIELD-PROVEN DURABILITY

Heavy-duty stamping with tight tolerances creates components that withstand extreme agricultural conditions and mechanical stress.

SEASONAL RELIABILITY

Proven on-time delivery performance ensures agricultural equipment manufacturers meet critical planting and harvest season deadlines.

PRECISION AGRICULTURE READY

Complex geometries and tight tolerances support modern GPS-guided and automated agricultural equipment requirements.

Why Agricultural Equipment Manufacturers Choose AMG?

Agricultural Equipment Expertise

Decades of experience manufacturing components for John Deere and other agricultural industry leaders

Heavy-Duty Stamping Capacity

20 presses from 18-300 tons handle thick materials required for robust agricultural applications

Weather-Resistant Materials

Expertise in stainless steel and corrosion-resistant alloys for superior field performance

Seasonal Production Flexibility

Proven ability to meet critical agricultural manufacturing deadlines during peak seasons

Progressive Die Efficiency

Complex agricultural components produced efficiently with minimal material waste

Custom Tool & Die Design

In-house tooling capabilities for specialized agricultural equipment requirements

ISO 9001:2015 Quality

Certified quality systems ensuring consistent agricultural component performance

High-Volume Agricultural Production

Scalable production from prototypes to 50,000+ units for seasonal equipment demands

Complete Agricultural Solutions

Integrated stamping, welding, and finishing services for complete equipment assemblies

Field-Tested Reliability

Components proven in demanding agricultural environments across multiple farming seasons

Agricultural Metal Stamping Specifications

| Capability | Details |

|---|---|

| Precision Metal Stampings | Presses: 20 stamping presses (18-300 tons), 12 straight-sided (80-300 tons), 8 OBI (45-150 tons) Die Types: Progressive, compound, draw, flange, trim Gauge: 0.010" to 0.250" Material Types: Ferrous and non-ferrous Production Scope: Prototypes to production Support: Engineering, project management, tool design Inspection: CMM measurement and statistical process control |

Agricultural Manufacturing Insights

Auto Parts Manufacturers: How Custom Metal Fabrication Plays a Crucial Role

By Melissa Brooks

Fri May 16 2025

Discover how custom metal fabrication drives precision, performance, and cost savings for auto parts manufacturers. Learn about key processes, materials, and automotive applications.

Read More

What Is Metal Stamping? Exploring the Key Benefits and Applications in Manufacturing

By Melissa Brooks

Fri May 09 2025

Discover metal stamping fundamentals, key benefits, and manufacturing applications. Learn about processes, materials, design considerations, and quality control best practices.

Read More

Why Cheap Metal Stamping Can Cost You More in the Long Run

By Melissa Brooks

Tue Mar 18 2025

Discover the hidden costs of budget metal stamping suppliers and learn how to evaluate true value beyond upfront pricing. Quality matters for your bottom line.

Read More

Agricultural Metal Stamping FAQs

Ready to Enhance Your Agricultural Equipment Manufacturing?

Partner with AMG Industries for precision metal stamping solutions that deliver the durability and reliability agricultural equipment demands.

Request a QuoteTrusted by Industry Leaders