Automotive Metal Stamping Services

Precision metal stamping solutions for automotive manufacturers. Our advanced stamping capabilities deliver the high-volume, tight-tolerance components needed for modern vehicles, from body panels to safety-critical components that meet stringent automotive standards.

Trusted by Industry Leaders

Metal Stamping Challenges Limiting Your Automotive Production?

Automotive manufacturers face intense pressure for zero-defect quality, just-in-time delivery, and cost reduction. Traditional stamping limitations can compromise production efficiency and quality standards that automotive OEMs demand.

Quality Control Failures

Inconsistent stamping quality leads to assembly line stops, costly rework, and potential safety recalls that damage brand reputation and profitability.

Just-in-Time Delivery Pressure

Production delays and supply chain disruptions disrupt automotive assembly lines where every minute of downtime costs thousands in lost production.

High-Volume Consistency Issues

Maintaining precise tolerances and surface quality across hundreds of thousands of automotive components creates significant manufacturing challenges.

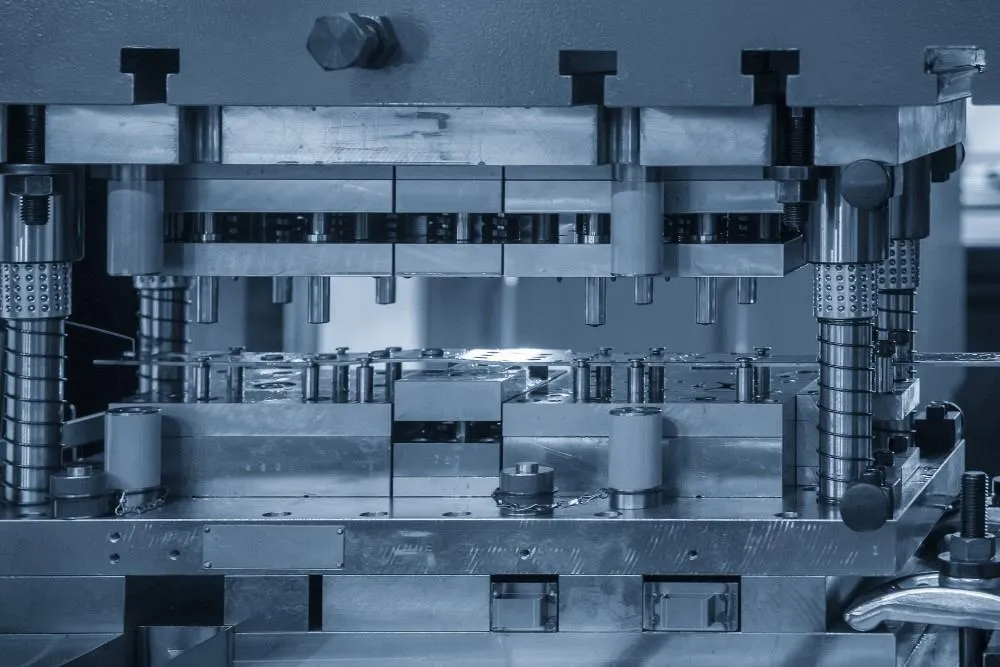

Advanced Automotive Stamping Excellence

Our 20 precision stamping presses, ranging from 18 to 300 tons, are specifically calibrated for automotive-grade materials and tolerances. We stamp high-strength steel, aluminum alloys, and advanced automotive materials that meet crash safety and fuel efficiency requirements.

Automotive components demand exceptional precision and consistency. Our progressive die systems create complex body panels, chassis components, and safety-critical parts with the tight tolerances required for modern vehicle assembly and crash performance.

From prototype vehicle development to high-volume automotive production, our ISO 9001:2015 certified processes ensure every automotive component meets the demanding quality standards required by Ford, Volvo, General Motors, and other automotive OEMs we serve.

Our experienced tool and die team understands automotive manufacturing cycles, working closely with automotive engineers to optimize part designs for stamping efficiency, material utilization, and assembly line integration.

Automotive Metal Stamping Advantages

ZERO-DEFECT QUALITY

Precision stamping with tight tolerances and rigorous quality control ensures automotive components meet stringent safety and performance standards.

JUST-IN-TIME RELIABILITY

Proven on-time delivery performance ensures automotive assembly lines maintain production schedules without costly interruptions or inventory buildup.

HIGH-VOLUME PRECISION

Consistent quality across hundreds of thousands of automotive components supports efficient assembly line operations and vehicle quality standards.

Why Automotive Manufacturers Choose AMG?

Automotive OEM Experience

Decades of experience manufacturing components for Ford, Volvo, General Motors, and other leading automotive manufacturers

High-Volume Automotive Production

20 presses from 18-300 tons handle automotive production volumes from prototypes to millions of components annually

Advanced Automotive Materials

Expertise in high-strength steels, aluminum alloys, and advanced materials required for modern vehicle safety and efficiency

Just-in-Time Manufacturing

Production planning and delivery systems designed to support automotive assembly line schedules and inventory management

Progressive Die Technology

Complex automotive components produced efficiently with minimal material waste and optimal cycle times

Automotive Tool & Die Expertise

In-house tooling capabilities for specialized automotive component requirements and rapid prototype development

ISO 9001:2015 Automotive Quality

Certified quality systems ensuring consistent automotive component performance and traceability

Scalable Automotive Operations

Flexible production capacity to support automotive model launches, production ramp-ups, and seasonal variations

Complete Automotive Solutions

Integrated stamping, welding, and finishing services for complete automotive assemblies and sub-systems

Automotive Metal Stamping Specifications

| Capability | Details |

|---|---|

| Precision Metal Stampings | Presses: 20 stamping presses (18-300 tons), 12 straight-sided (80-300 tons), 8 OBI (45-150 tons) Die Types: Progressive, compound, draw, flange, trim Gauge: 0.010" to 0.250" Material Types: Ferrous and non-ferrous Production Scope: Prototypes to production Support: Engineering, project management, tool design Inspection: CMM measurement and statistical process control |

Automotive Manufacturing Insights

Auto Parts Manufacturers: How Custom Metal Fabrication Plays a Crucial Role

By Melissa Brooks

Fri May 16 2025

Discover how custom metal fabrication drives precision, performance, and cost savings for auto parts manufacturers. Learn about key processes, materials, and automotive applications.

Read More

What Is Metal Stamping? Exploring the Key Benefits and Applications in Manufacturing

By Melissa Brooks

Fri May 09 2025

Discover metal stamping fundamentals, key benefits, and manufacturing applications. Learn about processes, materials, design considerations, and quality control best practices.

Read More

Why Cheap Metal Stamping Can Cost You More in the Long Run

By Melissa Brooks

Tue Mar 18 2025

Discover the hidden costs of budget metal stamping suppliers and learn how to evaluate true value beyond upfront pricing. Quality matters for your bottom line.

Read More

Automotive Metal Stamping FAQs

Ready to Enhance Your Automotive Manufacturing?

Partner with AMG Industries for precision metal stamping solutions that deliver the quality, consistency, and reliability automotive production demands.

Request a QuoteTrusted by Industry Leaders