Heavy Truck Laser Cutting Services

Precision laser cutting solutions for heavy truck manufacturers. Our advanced fiber optic technology delivers the strength, accuracy, and reliability needed for commercial vehicle production, from heavy-duty chassis components to structural parts that meet demanding heavy truck industry standards.

Trusted by Industry Leaders

Traditional Cutting Limiting Your Heavy Truck Production Efficiency?

Heavy truck manufacturers face intense pressure for structural integrity, regulatory compliance, and operational durability. Traditional cutting methods create bottlenecks that compromise the strength and precision heavy truck production demands.

Structural Integrity Issues

Traditional cutting methods compromise heavy truck materials and create inconsistent edge quality that leads to structural weaknesses and potential safety concerns in commercial vehicles.

Heavy Material Processing Delays

Tooling requirements for traditional cutting slow production of thick heavy truck materials, creating bottlenecks that disrupt commercial vehicle assembly schedules.

Limited Heavy-Gauge Capability

Traditional cutting struggles with thick, high-strength materials required for heavy truck chassis and structural components needed for commercial vehicle durability.

Advanced Laser Cutting for Heavy Truck Excellence

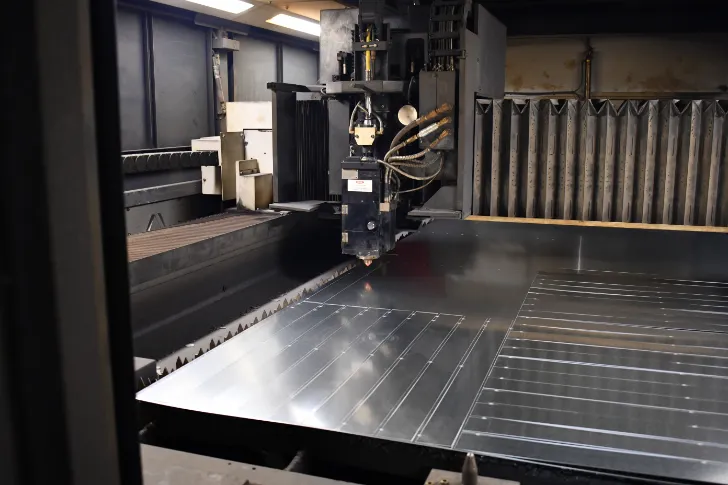

Our Mitsubishi ML3015eX F40 fiber optic laser systems deliver the precision and power heavy truck manufacturers need for commercial vehicle production. With 8000 watts of cutting power and travel speeds up to 50 meters per minute, we process heavy-gauge materials with exceptional quality and structural integrity.

Heavy truck components demand superior edge quality and material optimization for structural strength. Our nitrogen-atmosphere cutting eliminates oxidation while delivering burr-free edges perfect for welding and assembly. Advanced nesting software maximizes material utilization, reducing waste on expensive heavy truck alloys.

From prototype commercial vehicle development to high-volume heavy truck production, our laser cutting accommodates the robust requirements and complex geometries needed for commercial vehicles. Quick setup times support production schedules while maintaining the structural integrity heavy truck assembly requires.

Our engineering team understands heavy truck manufacturing requirements, working with commercial vehicle designers to optimize part designs for laser cutting efficiency while maintaining the structural strength and regulatory compliance standards required for heavy trucks.

Heavy Truck Laser Cutting Advantages

COMMERCIAL-GRADE PRECISION

Clean, consistent edges with ±0.005" tolerances ensure heavy truck components meet stringent quality standards for structural integrity and commercial vehicle performance.

RAPID PRODUCTION FLEXIBILITY

No tooling requirements enable instant production changes for different heavy truck models, supporting flexible commercial vehicle manufacturing schedules.

HEAVY-GAUGE MATERIAL EXPERTISE

Advanced cutting capabilities for thick steel, reinforced alloys, and heavy materials support heavy truck structural requirements and commercial vehicle durability.

Why Heavy Truck Manufacturers Choose AMG?

Heavy Truck OEM Experience

Decades of experience manufacturing components for Mack Trucks, Kenworth, and other leading commercial vehicle manufacturers

High-Power Heavy Truck Production

8000-watt laser systems with speeds up to 50 meters per minute support heavy truck production volumes and commercial vehicle manufacturing schedules

Heavy-Gauge Material Expertise

Expertise cutting thick steel, reinforced alloys, and heavy materials critical for commercial vehicle structural integrity and durability

Commercial Vehicle Manufacturing Support

Rapid setup capabilities and flexible production scheduling designed to support heavy truck assembly line requirements and fleet delivery schedules

Material Optimization Technology

Advanced nesting software minimizes waste on expensive heavy truck materials, reducing per-part costs for commercial vehicle production

Heavy Truck Quality Standards

ISO 9001:2015 certified processes ensuring consistent heavy truck component quality and traceability for commercial vehicle applications

Complex Heavy Truck Geometries

Fiber optic precision enables intricate heavy truck designs for modern commercial vehicle functionality and structural requirements

Prototype to Production Scalability

Seamless transition from heavy truck prototype development to commercial vehicle production runs

Complete Heavy Truck Solutions

Integrated laser cutting, stamping, welding, and finishing services for complete heavy truck assemblies and commercial vehicle systems

Heavy Truck Laser Cutting Specifications

| Capability | Details |

|---|---|

| Laser Cutting | Equipment: Two Mitsubishi 2D flat bed laser cells with ML3015eX F40 lasers Technology: Fiber optic Materials: Carbon steel, stainless steel, aluminum, steel Specifications: Maximum laser output 8000 watts, cutting thickness 6.35 mm, nitrogen atmosphere Benefits: High precision, custom fixtures, optimized setup, low tooling cost for high-volume and prototypes |

Heavy Truck Manufacturing Insights

Showing related content plus our latest insights to give you more valuable information.

How to Compare Metal Fabrication Suppliers and What to Look For

By Melissa Brooks

Thu Jul 24 2025

Learn how to evaluate and compare metal fabrication suppliers with this comprehensive guide covering quality, capabilities, pricing, and more.

Read More

Sheet Metal Fabrication: A Step-by-Step Guide to the Process and Applications

By Melissa Brooks

Thu Apr 10 2025

Learn the complete sheet metal fabrication process from design to finishing. Discover materials, applications across industries, and best practices for successful projects.

Read More

How to Request a Metal Fabrication Quote: What Buyers Need to Know

By Melissa Brooks

Mon Jun 16 2025

Learn the essential steps for requesting accurate metal fabrication quotes, from preparation to comparison. Expert tips to get the best value and avoid common mistakes.

Read More

Heavy Truck Laser Cutting FAQs

Ready to Enhance Your Heavy Truck Manufacturing?

Partner with AMG Industries for precision laser cutting solutions that deliver the strength, quality, and reliability heavy truck production demands.

Request a QuoteTrusted by Industry Leaders