Advanced Laser Cutting Services

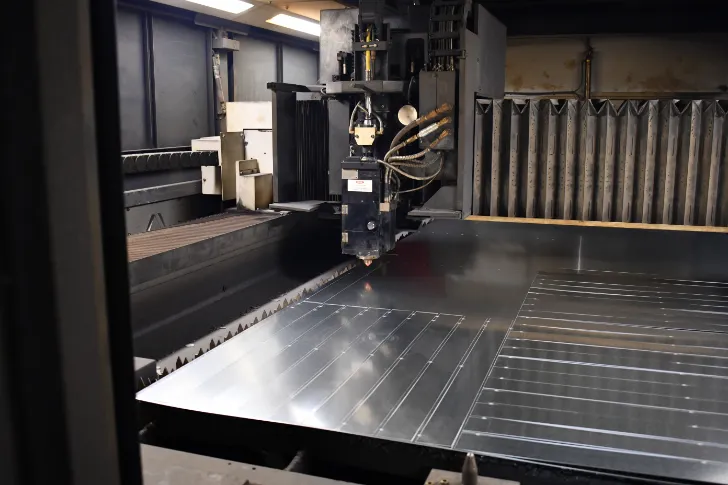

Our facility features two state-of-the-art Mitsubishi 2D flat bed laser cells, equipped with advanced fiber optic technology. This impressive laser cutting arsenal enables us to tackle a wide range of projects with unparalleled speed, accuracy, and flexibility.

Trusted by Industry Leaders

Traditional Cutting Challenges Slowing You Down?

Leading with Trumpf 3D laser cells and bespoke laser programs, AMG is outpacing competitors in precision cutting.

Poor Edge Quality

Traditional cutting methods leave burrs and rough edges requiring expensive secondary processing.

Limited Design Flexibility

Complex shapes and intricate patterns are impossible or prohibitively expensive with conventional methods.

High Tooling Costs

Traditional cutting requires expensive dies and tooling that limit design changes and increase costs.

Advanced Fiber Optic Laser Technology

Our two Mitsubishi 2D flatbed laser cells with ML3015eX F40 fiber optic lasers provide unmatched precision and flexibility. With 8000 watts of cutting power, we deliver clean, accurate cuts every time.

The fiber optic technology allows us to cut carbon steel, stainless steel, aluminum, and other metals up to 6.35mm thick. The nitrogen atmosphere ensures oxidation-free cuts with superior edge quality.

Our custom nesting and optimized setup procedures minimize material waste while maximizing throughput. Whether you need prototypes or high-volume production, our laser cutting delivers consistent quality with minimal tooling costs.

Laser Cutting Advantages That Drive Results

SUPERIOR PRECISION

Clean, burr-free edges with tolerances as tight as ±0.005" eliminate secondary operations.

RAPID TURNAROUND

No tooling requirements mean faster setup and immediate production starts.

DESIGN FLEXIBILITY

Complex geometries and last-minute changes are easily accommodated without tooling costs.

Why Choose AMG for Laser Cutting?

Fiber Optic Technology

8000-watt ML3015eX F40 lasers for superior cutting performance

High-Speed Processing

Travel speeds up to 50 meters per minute for rapid production

Material Versatility

Cuts steel, stainless, aluminum up to 6.35mm thick

Custom Fixtures

Proprietary fixturing for optimal material utilization

No Tooling Costs

Direct-from-CAD cutting eliminates expensive die requirements

Clean Cuts

Nitrogen atmosphere ensures oxidation-free, burr-free edges

Laser Cutting Specifications

| Capability | Details |

|---|---|

| Laser Cutting | Equipment: Two Mitsubishi 2D flat bed laser cells with ML3015eX F40 lasers Technology: Fiber optic Materials: Carbon steel, stainless steel, aluminum, steel Specifications: Maximum laser output 8000 watts, cutting thickness 6.35 mm, nitrogen atmosphere Benefits: High precision, custom fixtures, optimized setup, low tooling cost for high-volume and prototypes |

Laser Cutting Insights & Applications

Showing related content plus our latest insights to give you more valuable information.

How to Compare Metal Fabrication Suppliers and What to Look For

By Melissa Brooks

Thu Jul 24 2025

Learn how to evaluate and compare metal fabrication suppliers with this comprehensive guide covering quality, capabilities, pricing, and more.

Read More

Sheet Metal Fabrication: A Step-by-Step Guide to the Process and Applications

By Melissa Brooks

Thu Apr 10 2025

Learn the complete sheet metal fabrication process from design to finishing. Discover materials, applications across industries, and best practices for successful projects.

Read More

How to Request a Metal Fabrication Quote: What Buyers Need to Know

By Melissa Brooks

Mon Jun 16 2025

Learn the essential steps for requesting accurate metal fabrication quotes, from preparation to comparison. Expert tips to get the best value and avoid common mistakes.

Read More

Laser Cutting FAQs

Ready for Precision Laser Cutting?

Experience the speed and accuracy of fiber optic laser cutting for your next project.

Request Laser Cutting QuoteTrusted by Industry Leaders